2023-05-27

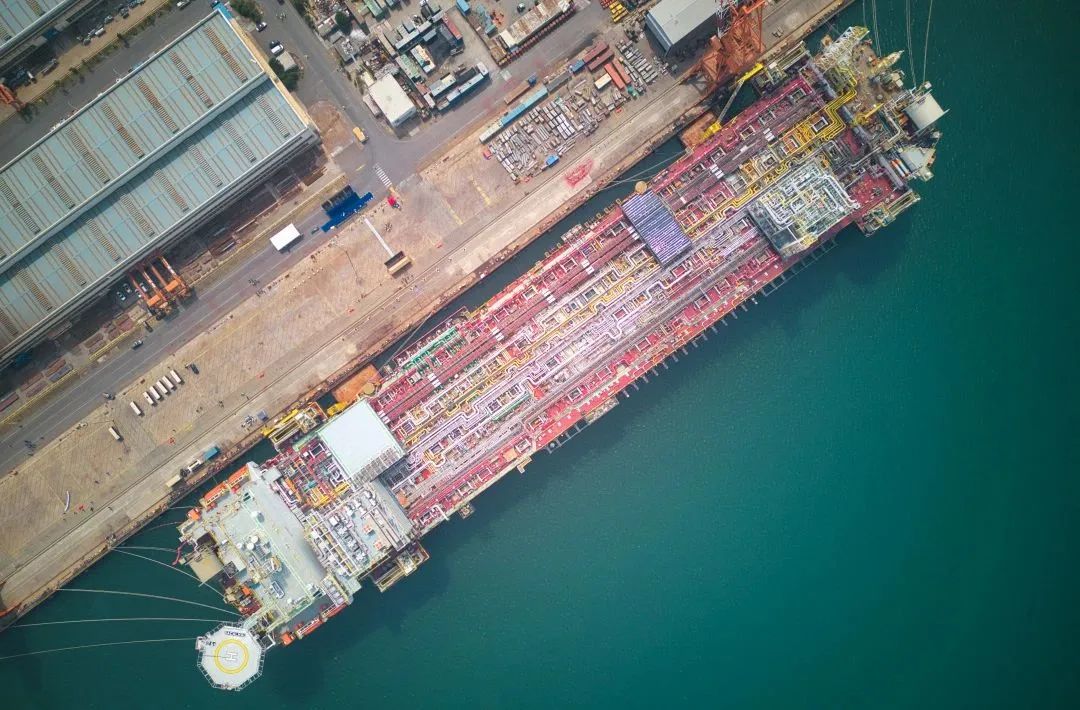

The first M350 floating, production, storage and offloading (FPSO) Bacalhau Hull, jointly developed by DSIC and MODEC, is successfully delivered in DSIC Dalian on May 26th, 2023. This M350 Hull design was developed jointly by DSIC and MODEC. With the successful delivery of this project, DSIC has made a breakthrough in the Chinese shipbuilding industry.

The FPSO vessel hull and living quarter building project (FPSO-8) is the seventh FPSO new built and delivered by DSIC. It is DSIC’s first collaboration on a newbuild FPSO Hull with international energy company, Equinor, headquartered in Norway and MODEC, the famous FPSO Contractor and Owner. This new type of FPSO vessel has moved from concept to practice, delivering digital operation and maintenance by utilizing full 3D design and visual construction. It is the world's first large offshore project designed with the latest rules and regulations of Det Norske Veritas. It can meet the special marine environmental conditions in Brazil and other regions, being suitable for oil and gas development operations in offshore waters around the world. It can help to significantly reduce owner operating costs.

The biggest storage capacity and production FPSO in Brazil

This FPSO will be deployed for offshore oil and gas production with processes of oil and gas separation, of slop oil/water treatment, power generation, heating, storage and transportation of crude oil products. The project is a comprehensive large-scale offshore oil production base that integrates personnel residence and production command system. The oilfield is the Santos Basin off the coast of Sao Paulo, Brazil. It is a floating production storage and offloading vessel with the largest storage and production capacity in Brazilian waters.

The record-breaking quantity of material and size

This FPSO is classified by Det Norske Veritas and flies the flag of Bahamas. The material scale and scale parameters are the largest in the world, with a total length of 364 meters, beam of 64 meters, depth of 33 meters, design draft of 22.65 meters, displacement of more than 460,000 tons, and a deck area of 17,400 square meters, equivalent to three standard football fields. After it is put into operation, it can process 220,000 barrels of crude oil each day. This production capacity is equivalent to the capacity of a ten square miles land based oil refinery facility. Among them, the oil and gas processing topsides modules weigh 50,000 tons. There are as many as 34,000 pipes spools in the whole vessel, weighing about 4,000 tons, and the total length of the cables is about 800,000 meters, which is equivalent to the straight distance from Dalian to Shanghai. The coating area is about 880,000 square meters, and the construction volume of each trade is three times that of ordinary super-large crude oil carriers.

Extensive application of non-ferrous materials

Successful and extensive application of a variety of long-term anti-corrosion materials such as titanium alloy pipes, heat-resistant alloy pipes, super duplex stainless steel pipes and the modified GRE pipe used for fire protection systems, breaking through the difficulties of welding process, painting process and installation process, achieving the FPSO in the oil field requires only a low level of maintenance and meets the 30 years design life without dry docking requirement. There are 22 cargo oil tanks with a full-load oil storage capacity of 2 million barrels. There are two offloading stations, the forward and aft one which will makes the offloading very easy and flexible during operations

Model of One Team, One Goal Cooperation

This project required high standards, a large quantity of materials, a tight schedule and massive interfaces; all of which was challenging to DSIC’s engineering, procurement and construction. In addition, the vessel construction was challenged by the COVID-19 pandemic. All the parties worked together with the spirit of “One Team, One Goal” to mitigate and overcome the difficulties with manpower and logistics. With combined efforts of all parties, we have achieved successful sail-away of Bacalhau FPSO Hull and Living Quarters, setting a model of full cooperation in the industry.

Fax of marketing Department:0411-66502818

Add:No.299,Guanghai Road,Changxingdao Economic Zone,Dalian,China(39°30'13 "N, 121°24'7" E)